Before we examine the types of motor control technologies out in the field, we need to understand the various loads that motors encounter in industrial applications.

Torque required to drive application does not depend on speed.

At any given moment, maximum torque may be needed in a range of speeds.

This is seen on constant speed machines like conveyor belts.

Torque required to drive application decreases as speed increases to maintain constant power output.

This is seen in lathes and grinding machines.

Torque required to drive application varies with the speed.

When a motor is used to move a fluid, the torque required increases with the square of the speed.

This is seen in pumps and fans where a motor is moving a fluid.

Many loads in industrial/commercial facilities are variable torque.

To adapt to varying loads, various technologies have been developed to ensure the motor runs at an optimal load for better efficiency.

Today, most motors use electronic speed controls, also known as VFD (Variable Frequency Drive).

These specifically-designed motors operate at two, three, or four speeds but aren't very efficient.

A smaller 'pony' motor is used when the load drops for a period of time.

By varying the input current magnitude, you can control the speed of a DC motor.

Similar to a CVT (Continuously Variable Transmission), these pulleys adjust the contact radius of the belt to change the transmission ratio.

Similar to a clutch, but adjusts the contact radius between two discs which changes the transmission ratio.

Similar to a torque converter, but the speed ratio is varied by increasing/decreasing the volume of oil in the device. A significant amount of power is lost to fluid friction.

The motor shaft is magnetically-coupled to the output shaft, and the strength of the magnetic field is varied to change the speed ratio.

VFDs vary motor's input frequency, which generates a change in the rotational speed of the magnetic fields, hence altering the speed of the rotor.

VFD System Overview (Wikipedia)

VFDs are inexpensive and reliable, and have the advantage of isolating the motor from the power supply. This reduces the motor's undesirable effect on the power factor of the facility's power supply.

Changing the width of voltage pulses changes the overall output voltage.

Frequency is changed to vary the speed of the motor.

Average PWM Magnitude (Wikipedia)

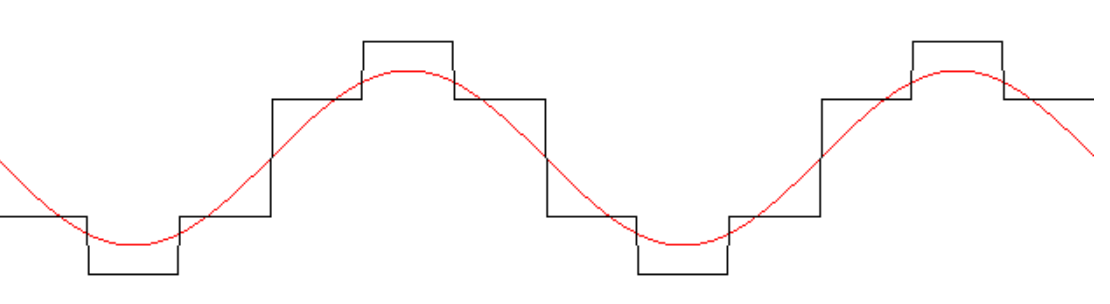

VSI creates a square-wave approximated sinusoidal voltage waveform.

Frequency of waveform is varied to change the motor speed.

Simulated Sinusoid with Square Waves (Wikipedia)

Similar to VSI but less expensive, less complexity, and ability to regenerate power.