Friction between standard V-belts and the sheave generates excess heat within the belt, resulting in an energy loss and shortened belt life. Notched V-belts or high torque drive belts (HTDB) reduces slip and allows the belt to bend around sheaves with less energy loss. Reduction in output speed and efficiency occurs when a standard V-belt slips within the groove of the sheave. Efficiency improvements have been found to range from 1% to 3% for notched V-belts and approximately 4% for HTDB.

Often the motor belt will be visible. Although it can be hard to identify belt type while the motor is operating, belt type is normally evident. If unsure, ask facility personnel or request to power off the motor.

The information needed to develop a highly efficient belt drive recommendation are motor nameplate data of motors being replaced (drive motor inventory), live readings of motor (if this information can be obtained), and the motor operation data (usually obtained from discussion with facility personnel.

The first step in developing this recommendation is to fill out a Motor Analysis Tool (MAT) for each of the proposed motors to obtain its Power Input and Energy Consumption. This can be done with either both the nameplate data and live readings information, or just the nameplate data. The steps for this can be seen in the Turning Off Idle Motors: Case 1 (Nameplate Data Available) and Case 2 (Nameplate Data and Live Reading Available).

We will now use the Efficient Belt Drives Template which can be downloaded from: Google Drive --> OSU EEC Template Directory --> Best Templates --> Efficient Belt Drives --> Efficient Belt Drives.xlsx

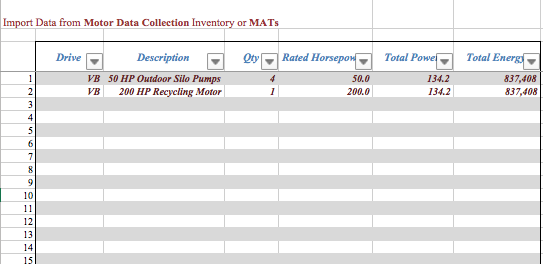

Using this template, we import the data obtained from the MAT tool onto the Belt Efficiency Import tab.

Figure 1: Belt Efficiency Import

The Drive, Description, Quantity, and Rated Horsepower information should be obtained during the assessment. The Total Power and Total Energy can be obtained after inputting all the information in the MAT tool.

Once this is filled up, we will be using the Drive Motor Inventory tab to complete the analysis.

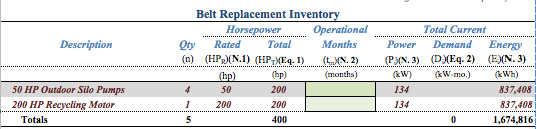

Figure 2: Belt Replacement Inventory

All cells will be automatically imported from the Belt Efficiency Import tab, except for the Operational Months and Total Current Demand column.

Total Current Demand = Power x Operational Months

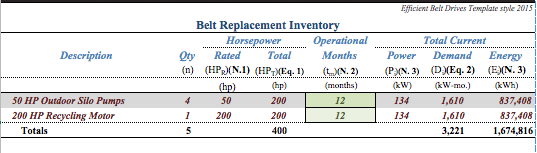

Once the Operational Months information has been filled in, it should look something like this:

Figure 3: Completed Belt Replacement Inventory

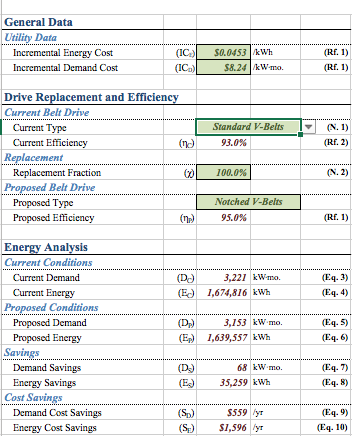

Next, the Analysis tab should be filled out with the Incremental Energy Cost and Incremental Demand Cost. These are obtained from the Utility Analysis done for the facility.

Figure 4: Analysis Tab

Notice the cells C10 (Current Belt Type) and C15 (Proposed Belt Type) are drop down menus. This is used to indicate what existing belt drives are used in the facility, and what belt drives the analyst is proposed to replace the existing ones with.

The savings of this recommendation comes from the difference in efficiencies of each belt drive.

Finally, do not forget to fill out the Narrative, Incentives, and Financial Analysis tab!